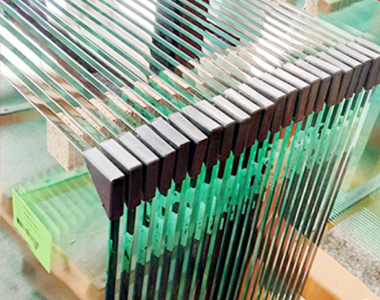

> Product Category : Heat soak test glass

> Product Number : Heat soak test glass

Features

Easy to clean: Smooth surface is easy to clean and maintain.

High transparency type: extremely high light transmittance, excellent visual effect.

Safety: After high-temperature treatment, the glass's impact and heat resistance have been enhanced.

Beautiful and elegant: modern design, suitable for various architectural styles, enhancing spatial grade.

Low self-explosion rate: Hot dip treatment and pre-detonating glass with impurities are used to reduce the self-explosion rate.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

4289.jpg)

.jpg)

0133.jpg)

.jpg)

5064.jpg)