Glass is a common material with many applications in architecture and furniture. To meet different needs, glass often requires various processing treatments. The following will introduce several common glass processing methods:

1. Selection of raw materials: Firstly, for glass processing, it is necessary to have glass raw materials. Ordinary glass processing factories do not produce raw materials, only large glass companies such as Xinyi Glass and South Glass Group produce them. The thickness of the original glass sheet also varies. If it is used to create architectural glass, a thickness between 4mm-15mm is generally selected. Due to the high-quality requirements of landmark building products for glass, tempered glass has a self-explosion phenomenon, and low iron glass with low iron content, also known as ultra white glass, is mostly used.

6830.jpg)

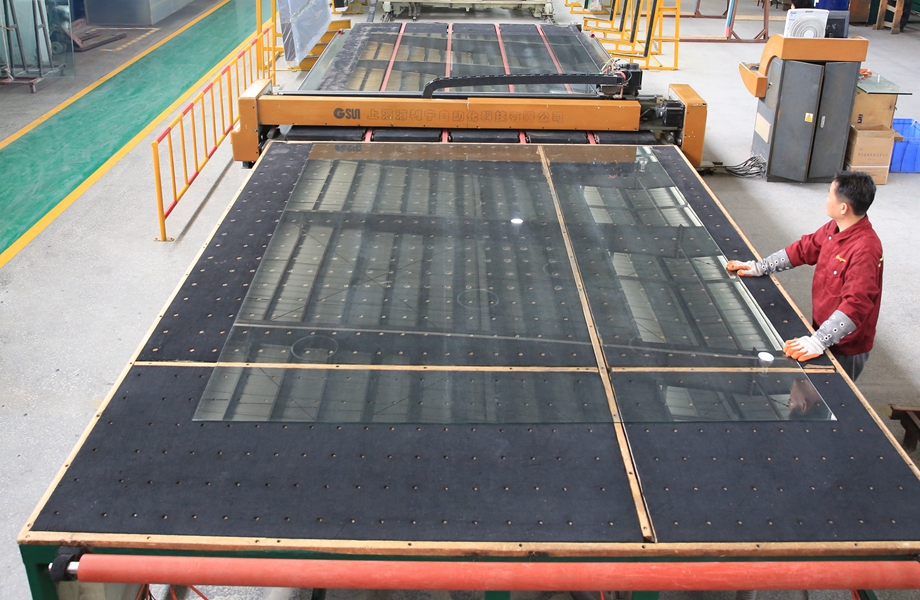

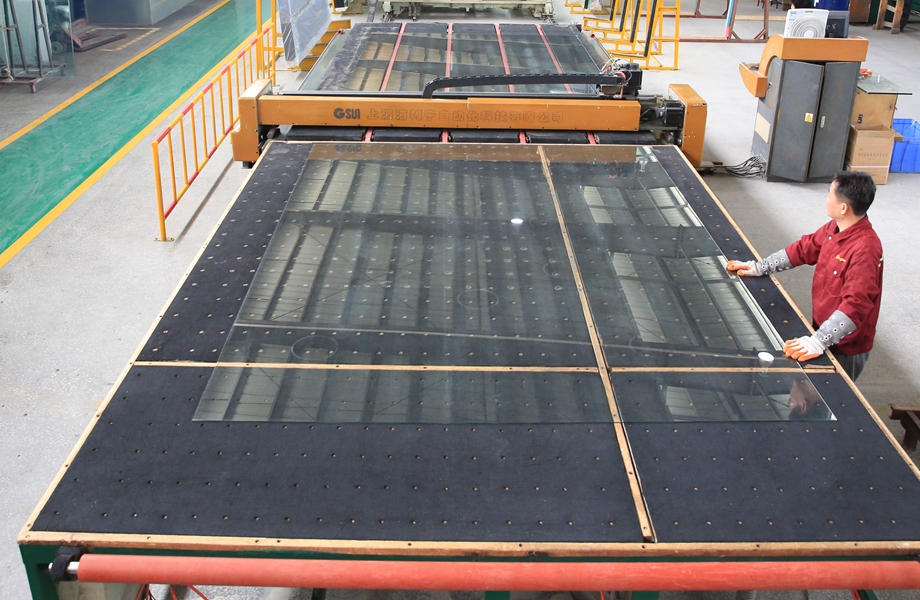

2. Glass size cutting: The size of the original piece itself is very large, usually over three meters long and two meters wide. Cutting can be said to be the first step in glass processing, and the staff will calculate how to cut this piece of raw material based on the dimensions on the customer's drawing. This algorithm must take into account the size consumed by the glass edge later on. Therefore, there is also the term 'tolerance'.

3. Glass edge grinding and chamfering: The freshly cut glass will scratch the hands, and the glass edges will be very sharp. Customers will also require edge grinding, but there are two types of edges: frosted edges and glossy edges. The frosted edges installed in the frame are sufficient to reduce costs. Polishing glossy edges is what customers require for glass aesthetics. After edge grinding, it is chamfering, and there are also specialized chamfering machines that can accurately pour out the desired R angle.

6021.jpg)

4. Tempering: Tempering can be divided into physical tempering and chemical tempering. Here, we are talking about physical tempering. Physical tempering is the process of heating glass in a tempering furnace to a certain degree, and then cooling it to increase its hardness after tempering. Customers will require tempered glass for safety. Tempered glass is also known as safety glass.

5902.png)

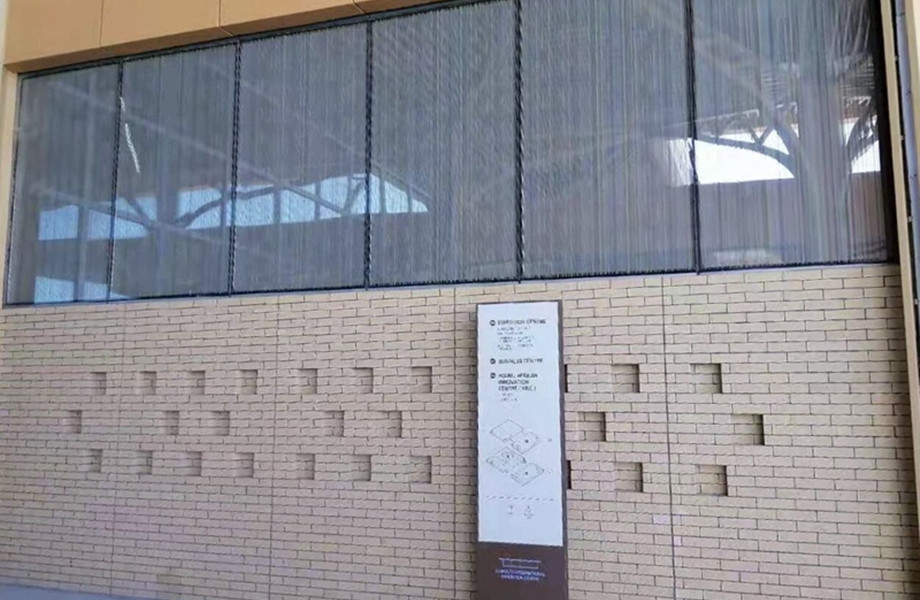

5. Screen printing: Some glasses go through this step because customers want to print certain patterns, company logos, etc. on the glass. Screen printing also includes high-temperature silk thread and low-temperature screen printing. High-temperature screen printing will be carried out before tempering. The screen printing room should be relatively clean. This way, the ink will not contain impurities. The effect of silk screen printing will be better.

glass partition processing factory supplier

6. Cleaning and testing packaging: The glass at the back must pass the inspection of the inspector before it can pass the inspection. Glass with problems will be selected, some will be scrapped, and some can be further processed. Good glass is coated with a film machine and then packaged in kraft paper or wooden boxes.

There are various processing methods for glass, and suitable processing methods can be selected according to specific needs to meet different application scenarios and aesthetic requirements.

6862.jpg)

4743.jpg)

7830.jpg)

5907.jpg)

6409.png)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)