Door and window glass not only has the functions of thermal insulation, sound insulation, lighting and viewing, but more importantly, it is the transparent wall (peripheral guardrail structure) of the home, which is responsible for building safety and protecting family members.

Therefore, the safety of glass products and their use is very important.

What is safety glass?

3230.jpg)

The use of door and window glass has a very important definition - safety glass: glass products with high strength, not easily broken, not easily broken, and not easy to harm people.

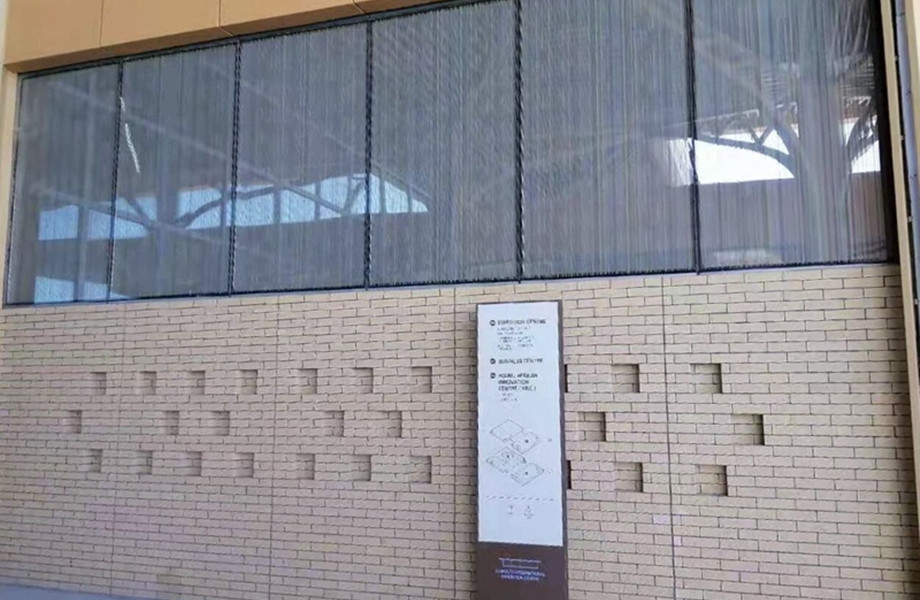

Clear tempered glass window door factory wholesale

The strength of tempered glass has been enhanced by high-temperature heat treatment in the tempering furnace, resulting in the formation of tensile stress on the surface. Compared to ordinary glass of the same thickness, its impact and bending resistance have been improved by about 3-5 times. Tempered glass breaks and forms small obtuse angle particles, which will not cause significant harm to the human body and are recognized as safe glass.

1097.jpg)

The laminated glass does not harm people, and the two pieces of glass are tightly bonded to the intermediate PVB/SGP film layer, through high-temperature and high-pressure methods. Compared to other glass, when broken, it will not fall all over the ground, but the vast majority of fragments will stick to the film, which has high impact strength and safety in use.

Nowadays, in home decoration doors and windows, merchants usually provide you with the most basic glass configuration, which is tempered insulated glass. For sunroofs, the basic configuration will be laminated glass, indoor partition glass, and glass doors. The basic configuration will generally be tempered glass.

So customers are buying safety glass, so why not rest assured?

Safety glass may not be safe in some cases:

The customer theoretically purchased safety glass, but the glass production did not pass the standards, resulting in insufficient quality of the glass.

4831.jpg)

The quality of the float glass sheets used for safety glass purchased by customers cannot be guaranteed. The widespread use of building glass has shown that float glass sheets are profitable, and businesses have established original sheet factories to produce defective float glass sheets, resulting in a high number of impurities in glass stones and causing self-explosion problems in later use. The most important thing to purchase glass is to determine the quality of the glass product. For example, KXG's glass raw materials are selected from well-known raw material manufacturers, selecting high-quality float glass to provide customers with high-quality products.

Different consumers have different perspectives on safety. For example, tempered glass not only needs to have sufficient strength, but also needs to pay attention to installation clearance. Glass installation requires a certain amount of clearance, and if the clearance is too small, it is easy to cause cracking.

Different application scenarios, what configuration of safety glass should be used, generally speaking: tempered insulating glass is used for doors and windows; tempered glass is used for indoor partitions, glass doors, and glass shower rooms (the thickness is usually used 8mm or 10mm); the top surface of the sunroom, glass canopy, and sunshade Pavilions, glass railings, etc., use tempered laminated glass.

2489.png)

Insulated building glass fctory wholesale

On the other hand, some consumers will want to improve the safety of glass, especially for high-floor doors and windows. Some consumers are worried that the glass will explode or accidentally break. The fragments may fall and injure people. The fundamental solution is to use insulated laminated glass, even if the glass breaks, there is no risk of the fragments falling. Another example is glass partitions and glass shower rooms. Some consumers are worried about accidents such as accidental bumps and thermal explosions. Tempered laminated glass can also be used to improve safety.

9204.png)

The tempered glass will have a self-explosion rate of three thousandths, which depends on the quality of the original glass (impurity content, mainly nickel sulfide), the pretreatment process of the deep processing enterprise (cutting, edge grinding process, etc.), tempering The parameter settings of the furnace are all related.

If you want to reduce the risk of glass self-explosion when using tempered glass, try to choose a more reliable glass deep processing factory, or choose ultra-clear glass. Ultra clear glass contains fewer impurities such as nickel sulfide, and the self-explosion rate will be lower than ordinary glass.

5152.jpg)

Clear glass vs ultra clear glass factory supplier

There is also a kind of processing that can reduce the self-explosion rate of glass. Using homogenized tempered glass, the tempered glass with potential self-explosion factors can be detonated in advance, which reduces the self-explosion rate after use and improves the safety of the glass used.

4316.jpg)

1427.jpg)

4325.jpg)

7568.jpg)

5598.png)

1042.png)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)