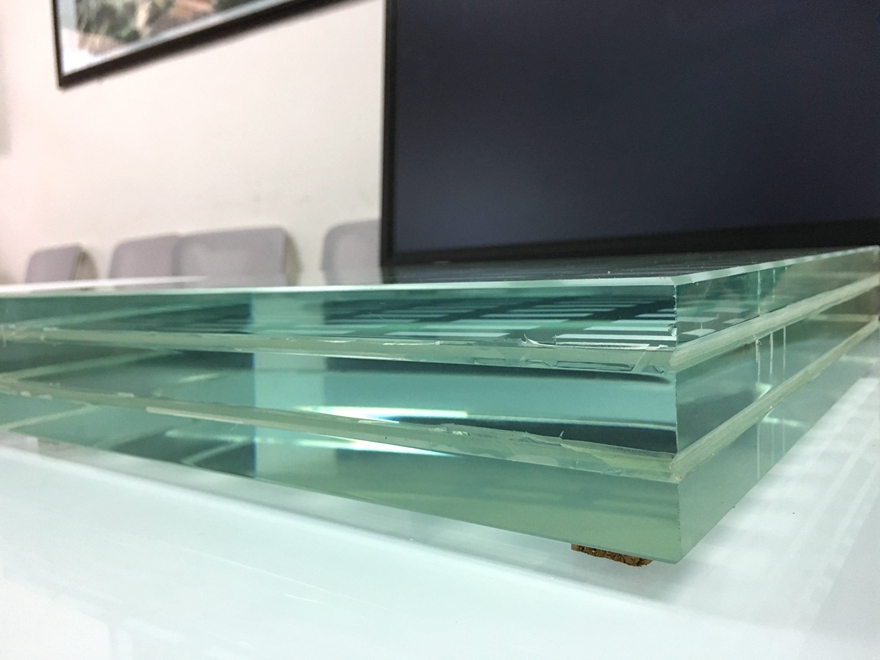

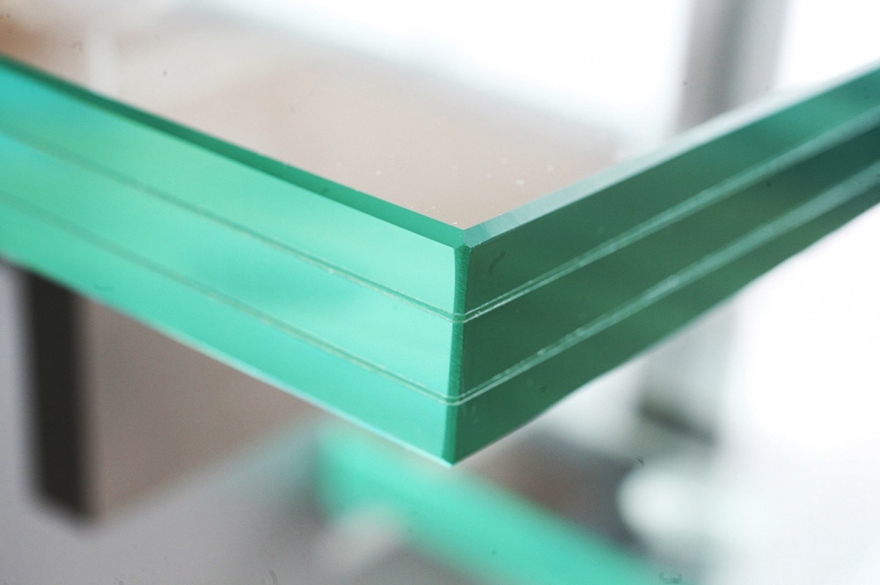

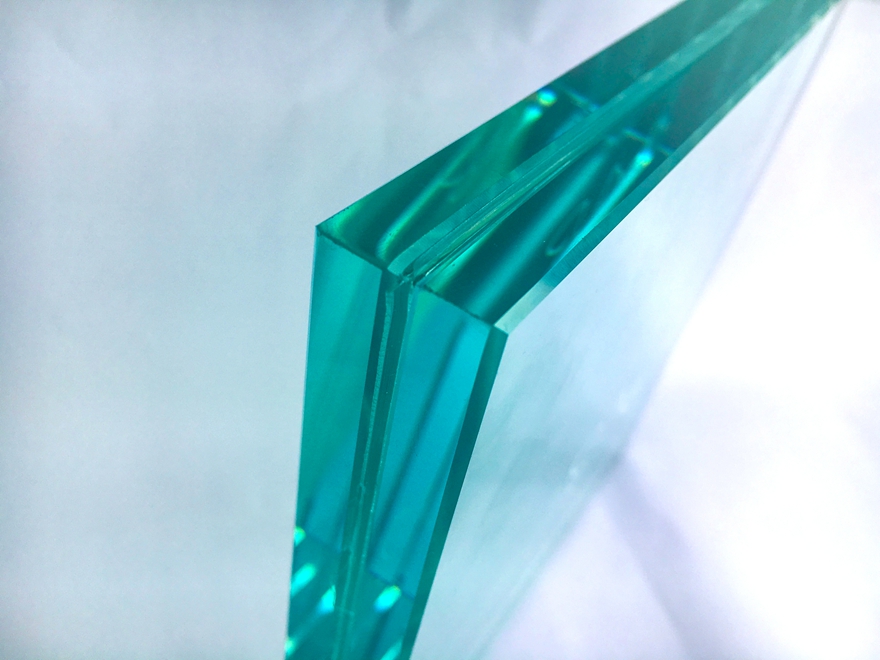

Laminated safety glass is a composite material such as glass, glass or plastic, separated by a middle layer and bonded through treatment. Common and mostly used are glass, separated by a middle layer and bonded through treatment. The main film of the laminated glass intermediate layer is the PVB, SGP, and EVA films. Due to the good impact resistance and bonding performance of this material, even if the glass is broken, external impact objects will not penetrate the glass, and glass fragments will not splash and cause personal injury or property damage.

Laminated glass is divided into dry method and wet method. The dry method laminated glass is to sandwich the film between two or more layers of glass and put it into the autoclave and hot pressure, suitable for mass production, is an industrial production, with the characteristics of high product strength, stable quality.

The wet method refers to the perfusion of the prepared binder slurry between two or more pieces of glass that have been closed in the mold, and makes the laminated glass by heating polymerization or light polymerization. The quality is not as stable as the industrial dry process, so it is not suitable for mass production.

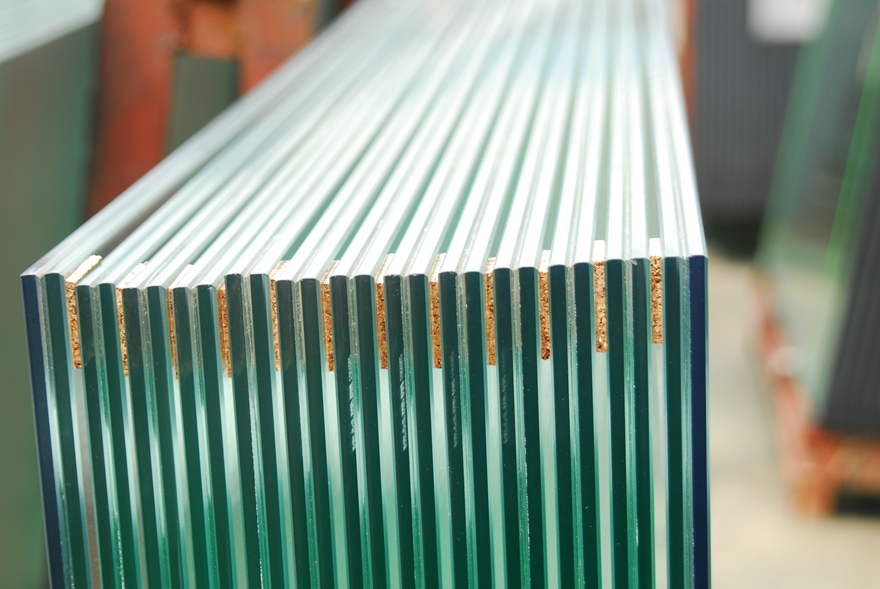

China industrial production of laminated glass must first go through the film chamber of the laminated production line, that is, the two or more pieces of glass are clamped together with film, and the room requires constant temperature, humidity and cleanliness. The sheet is rolled to make it more cohesive.

Finally, into the autoclave, also need a suitable high temperature, high pressure, make it to solve the residual air in the sandwich glass gas removal process, allowing the viscous activity of laminated glass film and making glass and film more cohesive. After the autoclave comes out, the glass is the finished product.

The laminated safety glass produced by KXG is made of high-quality high-grade float glass and imported laminated film, through advanced industrial production process, paying attention to the detail control between each process to ensure the quality of the products and provide customers with high quality and safe products.

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)