Safety performance is an important indicator for measuring building quality. Tempered glass and laminated glass are the two main types of safety glass. The characteristics and control measures of tempered glass have been extensively discussed earlier. Today, we will continue our exploration journey, focusing on the relevant knowledge of laminated glass. First, we will analyze the definition and main types of laminated glass.

The laminated glass belongs to one of the safety glass. It is a composite glass product made by sandwiching a flexible intermediate layer between two or more pieces of glass and then processing them at high temperature and high pressure.

.jpg)

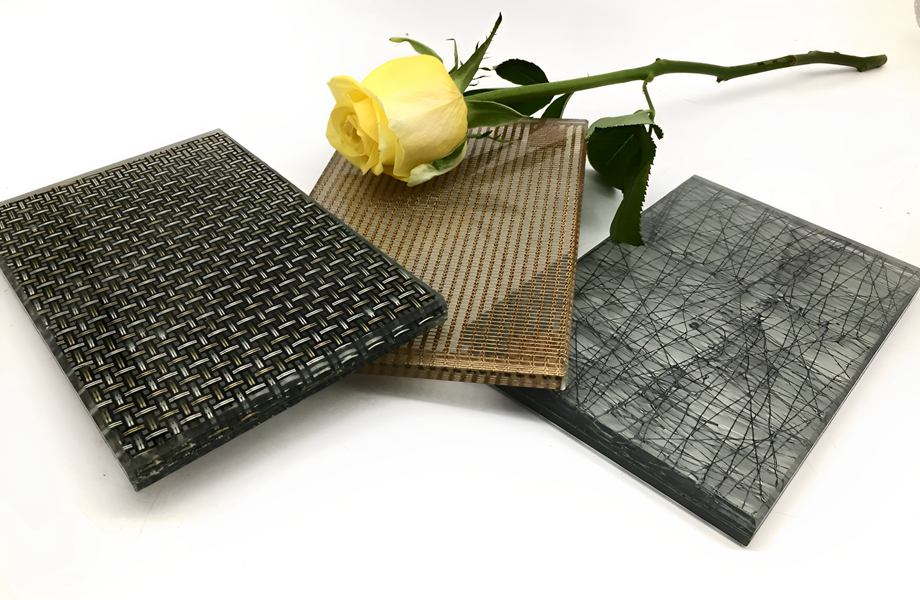

Common glass interlayers

The commonly used interlayer films for laminated glass include PVB, SGP, EVA, PET, etc. Among them, PVB and SGP films have the highest usage. The longest usage history.

PVB film (polyvinyl butyral)

Characteristics: Translucent film with good adhesion to glass, but poor adhesion to metal and water resistance.

Disadvantage: When the temperature is above 70℃, the adhesion will rapidly weaken, especially when used outdoors. It is also easy to peel off when exposed to a humid environment for a long time.

Application: Widely used in fields such as building curtain walls, guardrails, facades, office partitions, etc.

0503.jpg)

SGP film (Intermediate Ionic Membrane)

Features: Modified organic glass with better performance than PVB. High strength and toughness, good adhesion to glass and metal, good water resistance, and high humidity during use (<82 ° C). Even if the glass is damaged, SGP film can still retain a high residual strength.

Disadvantage: Compared to other intermediate films, the price is more expensive. The processing difficulty is higher, requiring higher temperature and pressure for processing.

Application: because of its high strength, high toughness, and other characteristics, it is usually used for special bulletproof and glass corridors, glass walkways, etc. in scenarios requiring high safety performance and high bearing capacity.

EVA film (ethylene polyvinyl acetate copolymer)

Features: Good adhesion to both glass and metal and good water resistance. Low melting point, easy to flow and process.

Disadvantages: Slightly poor tear resistance and weak UV resistance, prone to yellowing and blackening.

Application: Mostly used for decorating indoor home partitions, walls, etc., with strong decorative properties.

PET film (polyethylene terephthalate)

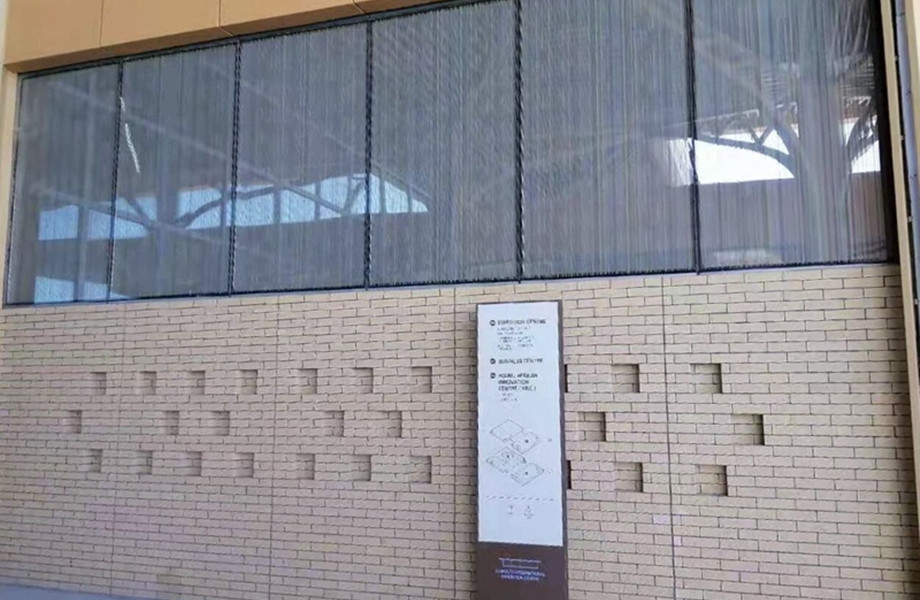

Characteristics: PET film has good toughness and can absorb impact force when glass breaks, allowing fragments to still adhere to the film and effectively reducing safety hazards caused by fragment scattering. If you need to display patterns on transparent glass, you can print the desired pattern on PET film and then bond it with two pieces of glass to make the pattern vivid.

.jpg)

The glass used in the KXG project at Danang Airport in Vietnam is made with this process, which has received unanimous praise from project clients.

Disadvantage: Compared to other intermediate films, the price is more expensive. The processing difficulty is higher, requiring higher temperature and pressure for processing.

Application: It is usually used in situations that require significant impact force, such as building glass, car windows, home decoration, etc. It is used as a sandwich material combined with two or more layers of glass to enhance strength, safety, and other functions.

.jpg)

Functions and characteristics of glass interlayer

Security

Due to the good toughness, strong adhesion, and penetration resistance of the intermediate layer, the glass will still stick tightly together after breaking without splashing, and objects are difficult to penetrate. Therefore, it has a safety protection effect on human and property. When used for high-rise building curtain wall glass, even if it breaks, it will not fall and cause harm to the outside. At the same time, it can also protect indoor people or objects from falling through the glass. Therefore, it belongs to the complete sense of safety glass.

.png)

UV transmittance

The middle layer of ordinary laminated glass, especially PVB film, has extremely strong ultraviolet absorption ability and can filter ultraviolet rays that pass through the laminated glass, with a filtering effect of up to 99%. This can not only protect indoor furniture, plastic products, textiles, etc. from fading and aging caused by ultraviolet radiation but also effectively reduce indoor temperature and air conditioning energy consumption.

KXG laminated glass manufactured

Sound insulation performance

The middle layer of laminated glass can absorb sound waves, especially PVB film. Can effectively block the propagation of noise. Compared with single-layer glass, laminated glass has better sound insulation performance, especially suitable for places that require high sound insulation, such as bedrooms, study rooms, etc.

.jpg)

Laminated glass not only plays the role of the ‘invisible guardian’ in building safety but also enhances the functionality and aesthetics of buildings through its many advantages. With the continuous progress of technology, the application of laminated glass will be more extensive, creating a safer, more comfortable, and better living environment for us.

6592.jpg)

5267.jpg)

8571.jpg)

0199.jpg)

2738.png)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)