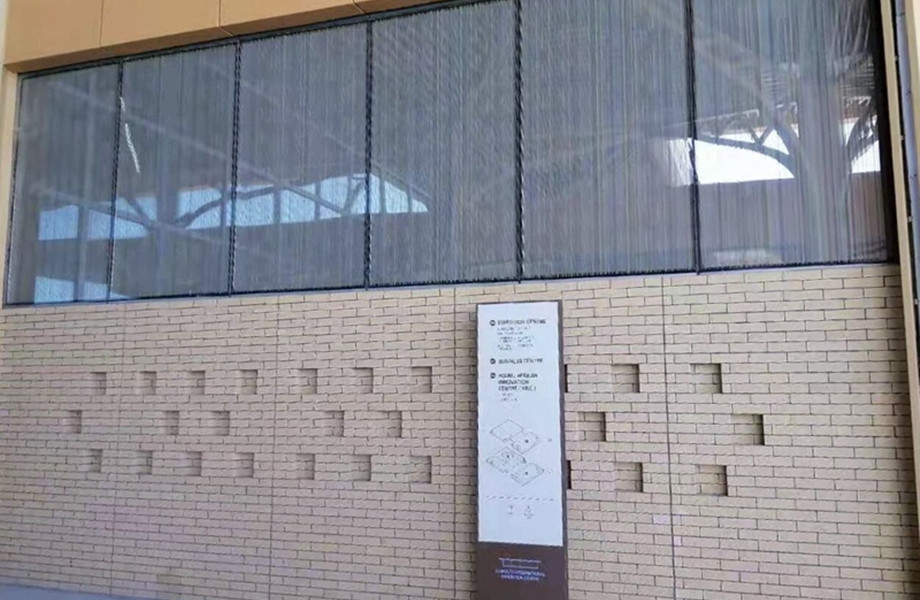

In modern glass products, in addition to its basic transparency and practicality, the edge quality of glass is an important factor that cannot be ignored. As a well-known manufacturer of architectural glass, KXG's grinding process for glass edges has been widely praised in the industry, and the brightness and precision of its edges add unique value to its products.

KXG glass grinding edge processing factory

.jpg)

The purpose of glass edging:

1. Grind off sharp edges and corners caused by cutting to prevent injury during use.

2. The small cracks and microcracks formed by cutting on the edge of the glass are ground away, eliminating local stress concentration and increasing the strength of the glass.

3. Perform different levels of quality processing on the glass edges, including rough grinding, fine grinding, and polishing.

6832.jpg)

KXG adopts five steps to achieve the bright edge effect of building glass edges. And KXG uses specialized equipment from well-known brands to complete the glass edging process, which is very precise.

ultra clear polish edge glass supplier

1. The bright edge of the glass edge is related to the grinding speed. KXG adopts a precision grinding standard of 2m/s for edge grinding at medium and low speeds, strictly controlling the edge grinding speed. Medium and low-speed edge grinding can reduce the occurrence of cracks, scratches, edge and corner breakage in glass, reduce glass loss, and provide customers with high-quality glass products.

4491.png)

2. Glass edge grinding wheel. The larger the number of wheels used for glass edge grinding, the finer and smoother the edges produced. KXG uses fully automatic glass edge grinding and is equipped with grinding wheels of different mesh sizes at different positions. The configuration of grinding wheel mesh sizes from the edge grinding end to the glass edge is increasing, from rough grinding to fine grinding and finally polishing. The grinding process is directly completed with fully automatic edge grinding, and the edges of the glass products are very transparent, which has been unanimously recognized by customers at home and abroad.

.jpg)

3. There are also certain requirements for the water quality when grinding glass edges. During the process of glass edge grinding, glass shavings, and residues are generated. To ensure the quality of edge grinding and the smoothness of the glass surface, KXG uses filtered water with a neutral pH value. Water technology is used to remove suspended particles and impurities in the water, soften metal ions such as calcium and magnesium in the water, and reduce scratches on the glass during edge grinding. Acidic water is corrosive and reacts with the glass to cause deterioration and damage to the glass surface, resulting in roughness or scratches. Using water with a neutral pH value has good cleaning ability, which can effectively remove stains on the glass surface, maintain the cleanliness of the edge grinding process, and improve the effectiveness and quality of glass edge grinding.

.jpg)

4. In addition to water quality requirements, there are also specific requirements for water temperature control. The water temperature for glass edge grinding should be controlled within an appropriate range, generally between 20-30℃ at room temperature. Excessive water temperature may cause the glass to expand and contract, resulting in uneven or broken edges. Water temperature control can ensure the quality of glass edge grinding.

custom polish tempered glass manufactured

5. Strict quality control. KXG implements a strict quality control system in the production process. Each piece of glass undergoes multiple inspections after processing, including visual inspection and gloss testing. This rigorous quality management ensures that every product meets high standards and that the brightness and smoothness of the edges are maintained.

The polishing and precision of KXG glass edges not only reflect its advanced technology and equipment but also embody its almost stringent pursuit of product quality. From raw material selection to every meticulous grinding step, to final quality assurance, KXG has demonstrated its professionalism and sense of responsibility as an industry leader. Therefore, whether in home decoration, architectural design, or other fields, choosing KXG glass is undoubtedly a wise choice for pursuing high-quality architectural glass products.

2637.png)

1035.jpg)

1993.jpg)

9779.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.jpg)

.jpg)